MC

The design and manufacturing vision of Minelli s.r.l. is fully accomplished in the company’s new range of shears – the MC & MC R series. Top of the range performance and excellent size – weight – power ratio make these shears stand out.

Special steels have been used for these products (Minelli shears are fully made from Hardox steel) and special attention has been given to structure. The result is highly firm and sturdy equipment, with enhanced cutting force. All shears can be supplied featuring a continuous 360° hydraulic rotation and saddle to be coupled to excavators or loaders.

Main features:

1 - Product made from Hardox steel, material that combines excellent mechanical characteristics and high wear resistance.

2 - Structure featuring internal cambered section and box-type exterior; one-piece fixed hook and movable hook. These characteristics added to the special steels used to make these products help limit torsion and force dispersion, thus improving cutting.

3 - Special attention has been given to the mouth- instead of being ‘wide and clean’, it shows a new geometry at the bottom to that material does not get jammed.

4 - Angled split by the optimised cylinder for better distribution of the splitting force and a more compact equipment.

5 - All main blades can be used on all 4 sides. The hook blade on 2 .

6 - Double guide for the movable hook.

7 - Hardened and straightened alloy steel bushings and bolt.

8 - Cylinder with brake, hardened and chromeplated rod, Hardox head, working pressure up to 400 bar.

9 - Speed valve

10 - ‘Protective’ design: All hydraulic components are inside the machine body.

11 - 360° continuous rotation unit.

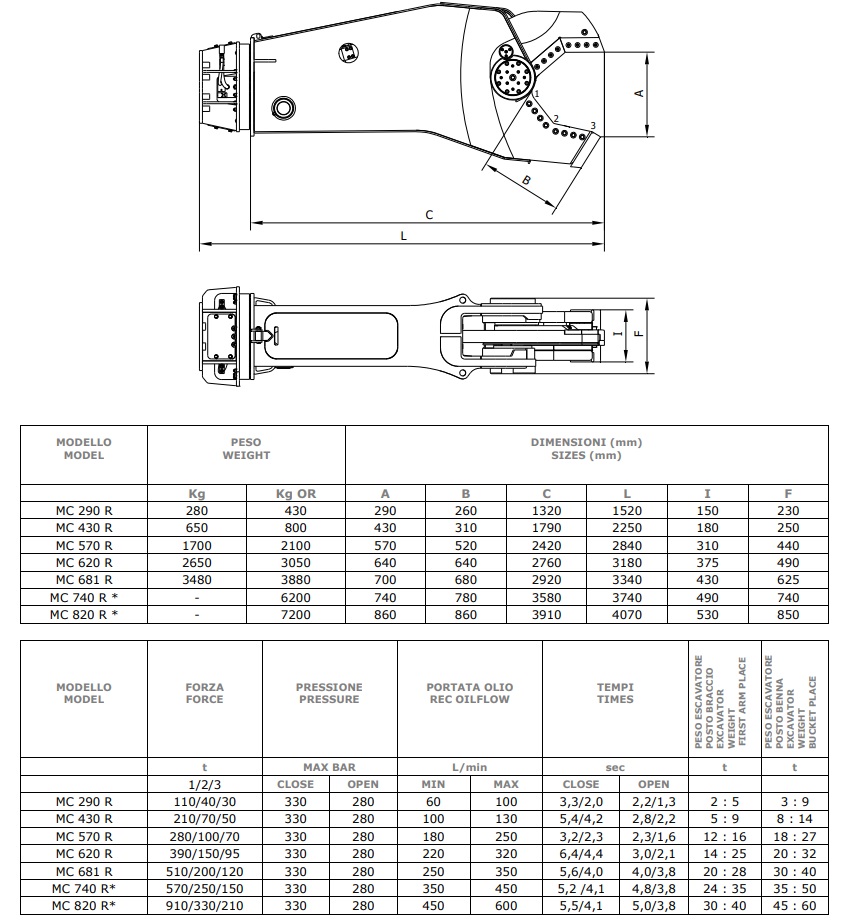

Data and weight are indicative: the company reserve the right to make any improvements and changes required for good operation, without giving advance notice.

MC 430 R, scrap - Watch the tool at work

For further information contact us at info@minellisrl.it, our specialized staff will take care of your request.